Sector Served

- Cement

- Rolling Mills

- Ball Mills

- Sag Mills

Cement Industry

The cement industry requires tough gearboxes for high torque requirements of this industry. This industry requires compact gearboxes for continuous operation under changing load conditions.

Krishna Gear is playing major in manufacturing gears related to cement industry. We build high quality spiral bevel gears/crown pinion gears, spur gears, helical gears, Sprocket gears, and pinion gears for many cement industry firm.

Rolling Mills

We are offering quality tested Rolling Mill Gear Boxes for rolling mills of high performing capacity. In this, the number of drives is equal to the number of mill stands or number of passes. The rolling mill gear boxes are highly durable and prove more cost effective in the long run.

These can be developed from casted iron and stainless steel. There could be one input three output gear box, coupled with one AC motor.

Ball Mills

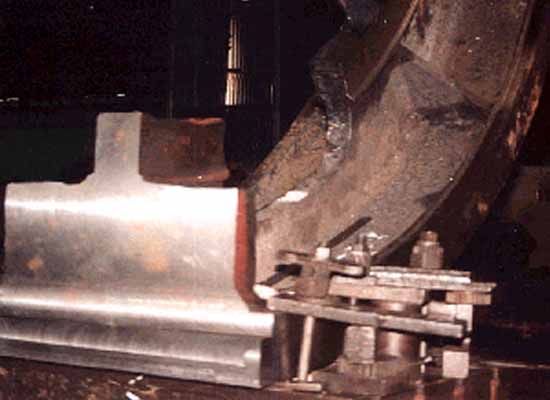

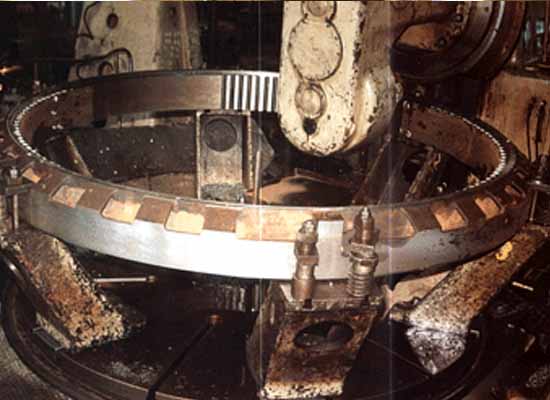

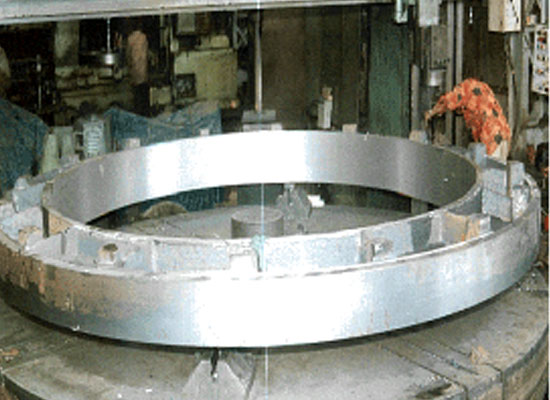

Two general classifications of gearing are used for ball Mill drives. These are the spur gear and the helical gear. Helical gearing may be either of the single helical or double helical (Herringbone) design.

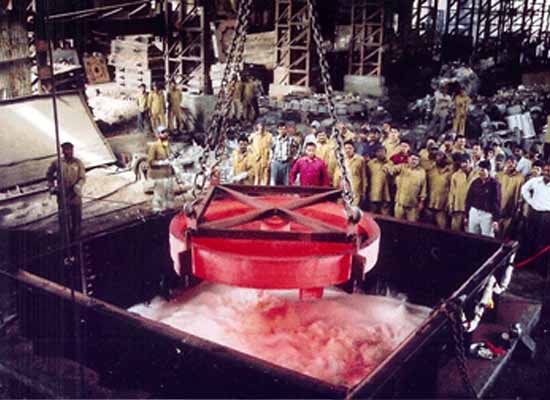

We make Complete MDX mill drive system; girth gear, pinion, mill drive gearbox, couplings, brakes, pedestal bearings and clutches providing a comprehensive mill drive system.

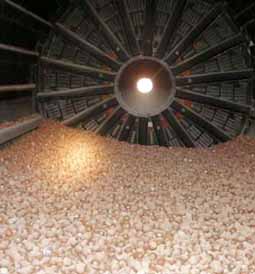

SAG Mills

Semi-Autogenous Grinding, which means that it utilizes steel balls in addition to large rocks for grinding. The SAG mills use a minimal ball charge of 6 to 15%. It has a large diameter and short length. It rotates, tumbling its contents, causing a breaking action.

The liner is made of wear resistant steel and fitted with lifters, which assist in raising the load as the mill rotates. The load consists of dry ore.